PRODUCTS

MECHANICAL PRESSING> EXTRUDER

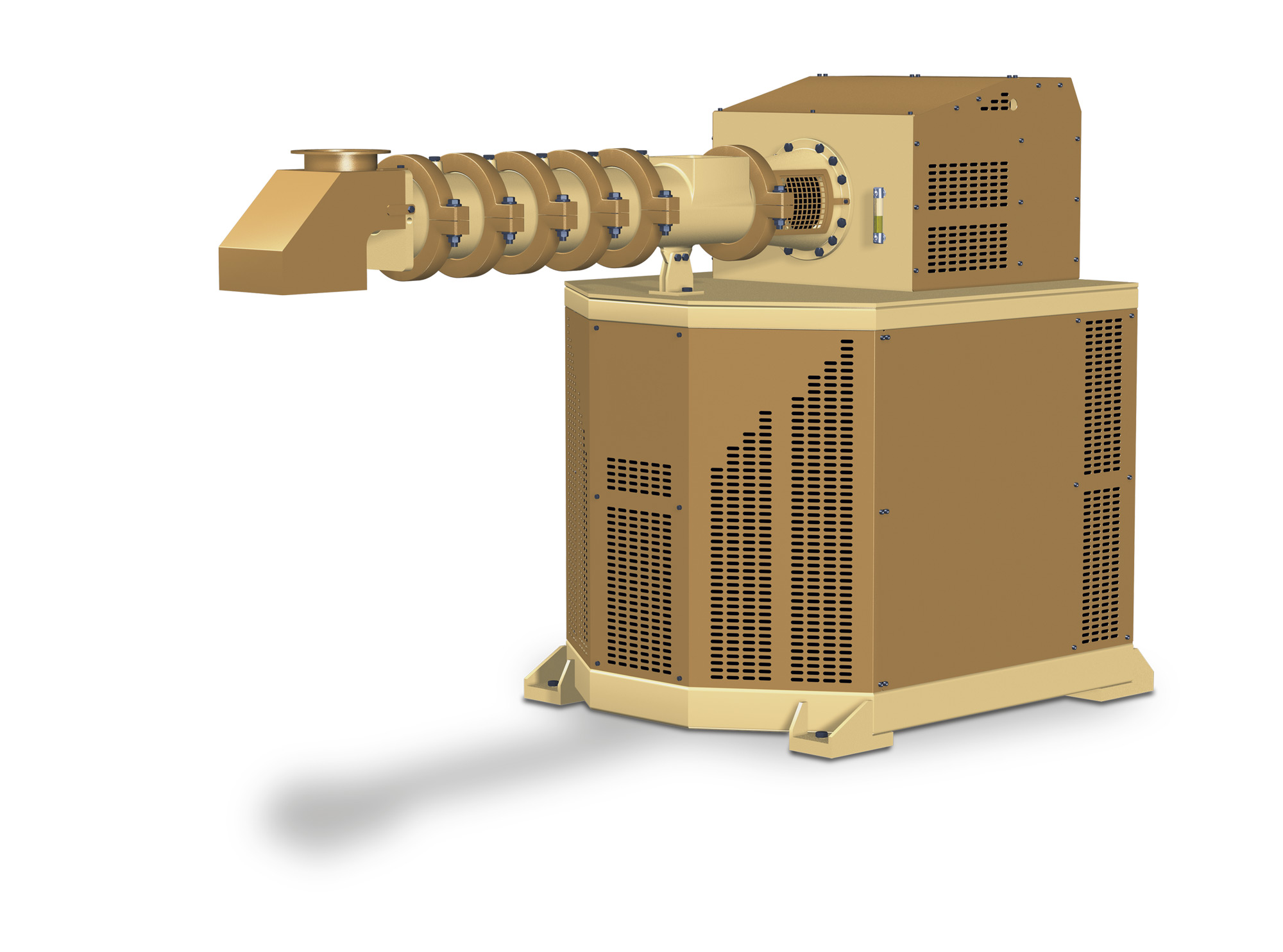

The extruder allows, through a high friction process that raises the temperature, the conditioning and preparation of oilseeds prior to the extraction process of vegetable oil by mechanical pressing.

Feeder / Automation

- Feeding screw of variable speed.

- Independent operation control.

- Vertical feeder for constant load.

- With a control system in plant, the operation of the feeder and the equipment can be automatized, thus allowing set points to be established that parameterize its operation in different scenarios, consequently being able to have preset responses or fault alarm indication.

- Feeding system startup needless of permanent supervision.

- Remote program of operating parameters regulation.

- Automatic feeding failures detection.

Extruder

- Self-supported equipment.

- Extruder body of easy access and exchangeability.

- Thermally-treated worms and diffusers built of high erosion resistance alloy.

- Axial bearing housing for axis force support.

- Independent lubrication system for axial bearing housing and reducer.

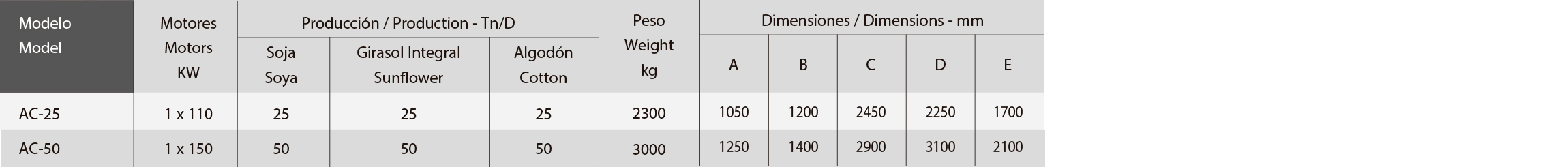

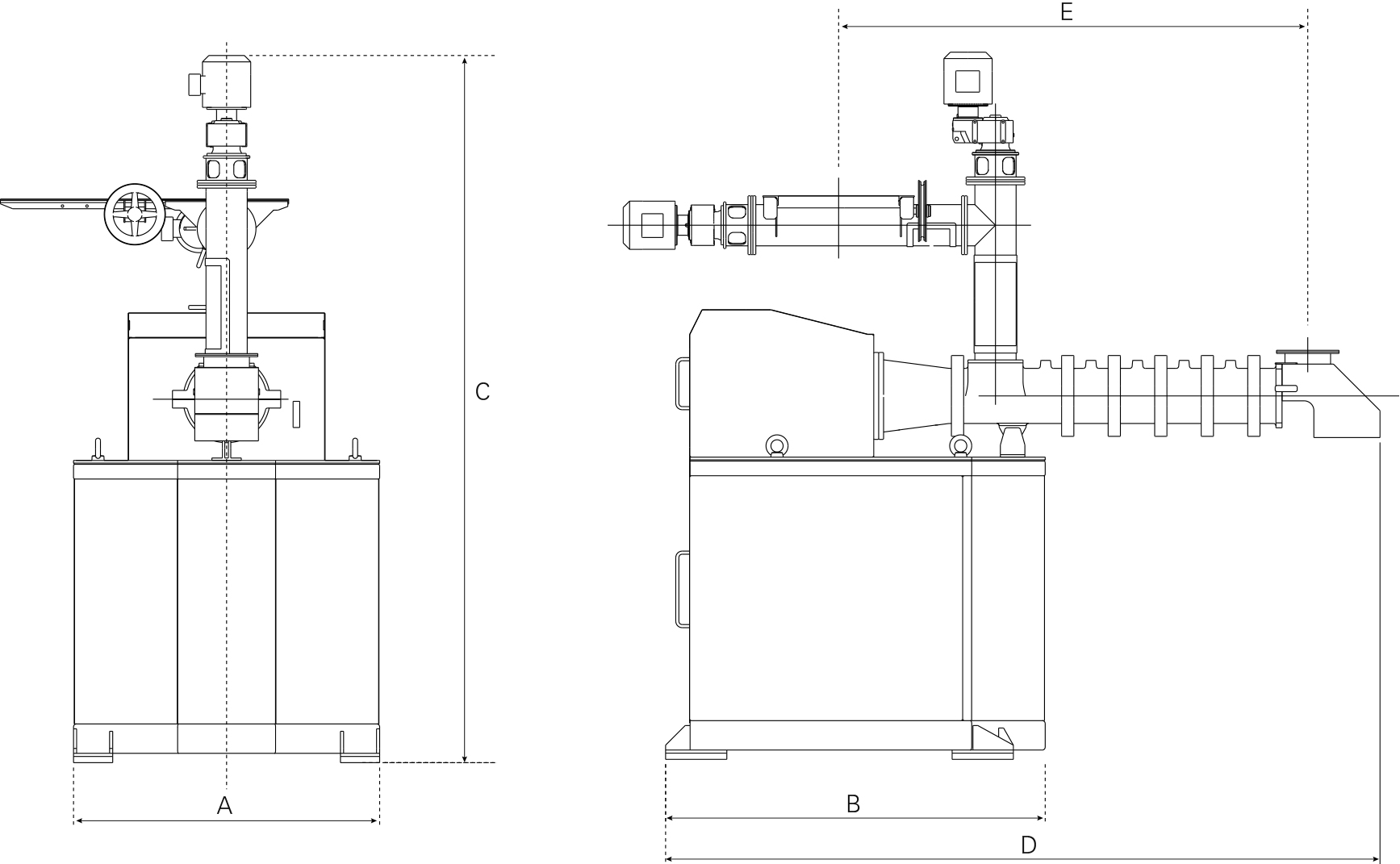

Technical Characteristics and Measures