PRODUCTS

PREPARATION > VERTICAL COOKER

The vertical cooker conditions the seeds by regulating temperature and humidity.

The main aims of the process are:

- To provide seed plasticity.

- To reduce oil viscosity.

- To bring about coagulation of proteins.

- To sterilize the seeds.

- To decontaminate undesirable components in the seeds.

Vertical Cooker

- The heating medium is water vapor in a pressure range of 6-8 bar. Seeds are heated to 90-110 °C for pressing and 65-72 °C for direct extraction.

- Certified by the EEC (European Economic Community) for elements exposed to pressure.

- Material passage system on each floor, mechanically operated and externally regulated.

- Stainless steel steam exhaust.

- Independent manhole per floor.

- High quality main operation reducer.

- Independent steam injection and condensed steam recollection system per floor.

- Axial bearing housing for vertical axle supporting.

- Specially designed stirrers in each floor.

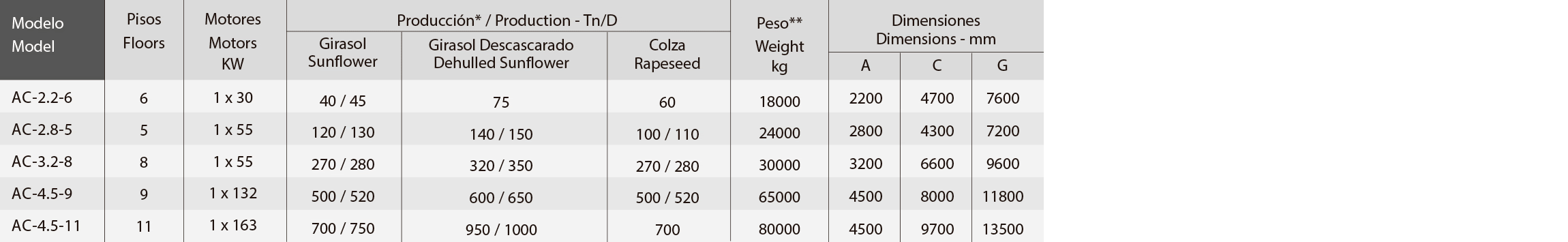

Technical Characteristics and Measures

* Please check for capacities for other oilseeds. ** Weight including legs and motor