PRODUCTS

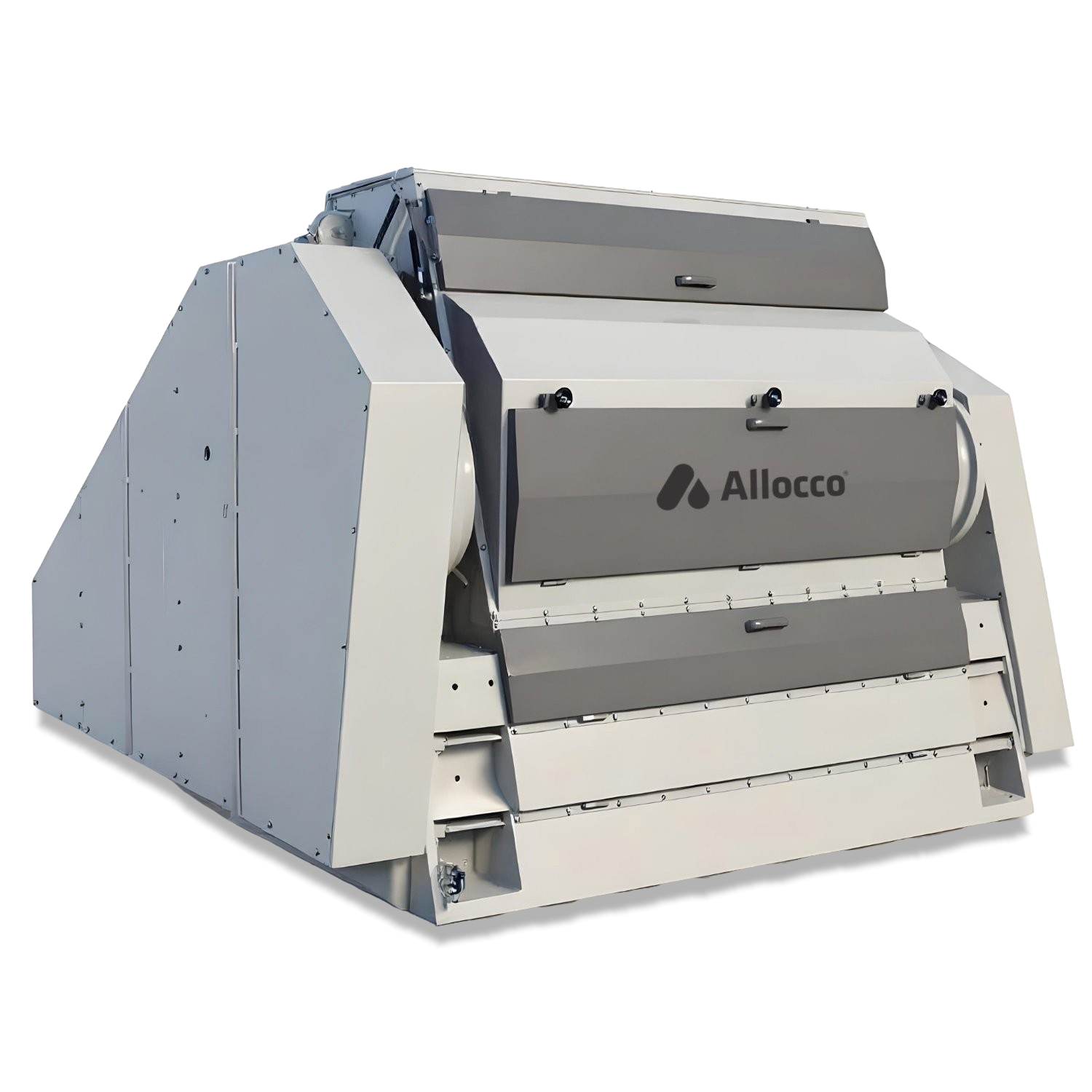

PREPARATION > FLAKER

Seed flaking yields an increase in efficacy in the oil extraction process.

This is achieved by passing the seed between smooth, large diameter rolls which usually produce flakes with a thickness of 0.3-0.4 mm. Flakes are produced by the friction between the rolls that spin at different speeds.

Feeder

- Rotary type, with permanent magnetic trap.

- Anti-magnetic threaded roll.

- Automatic feeding system with variable speed roll.

Flaker

- Split tiltable bearing boxes that facilitate the dismantling of the rolls.

- Opening and closing of the rolls by double effect hydraulic cylinders.

- High quality and first brand rolls.

- Easy access roll scrappers for maintenance.

- Structure, casing and cover belts lined with acoustic insulation material (In the AC-300 and AC-400 flaker).

- Roll adjustment hydraulic circuit with a security valve system that loosens the rolls in the presence of foreign materials.

Optional

- Hydraulic system for roll dismounting (For AC-400 only).

- Belt drive of 1 or 2 motors (In AC-400 only).

- Equipment for roll and board rectification.

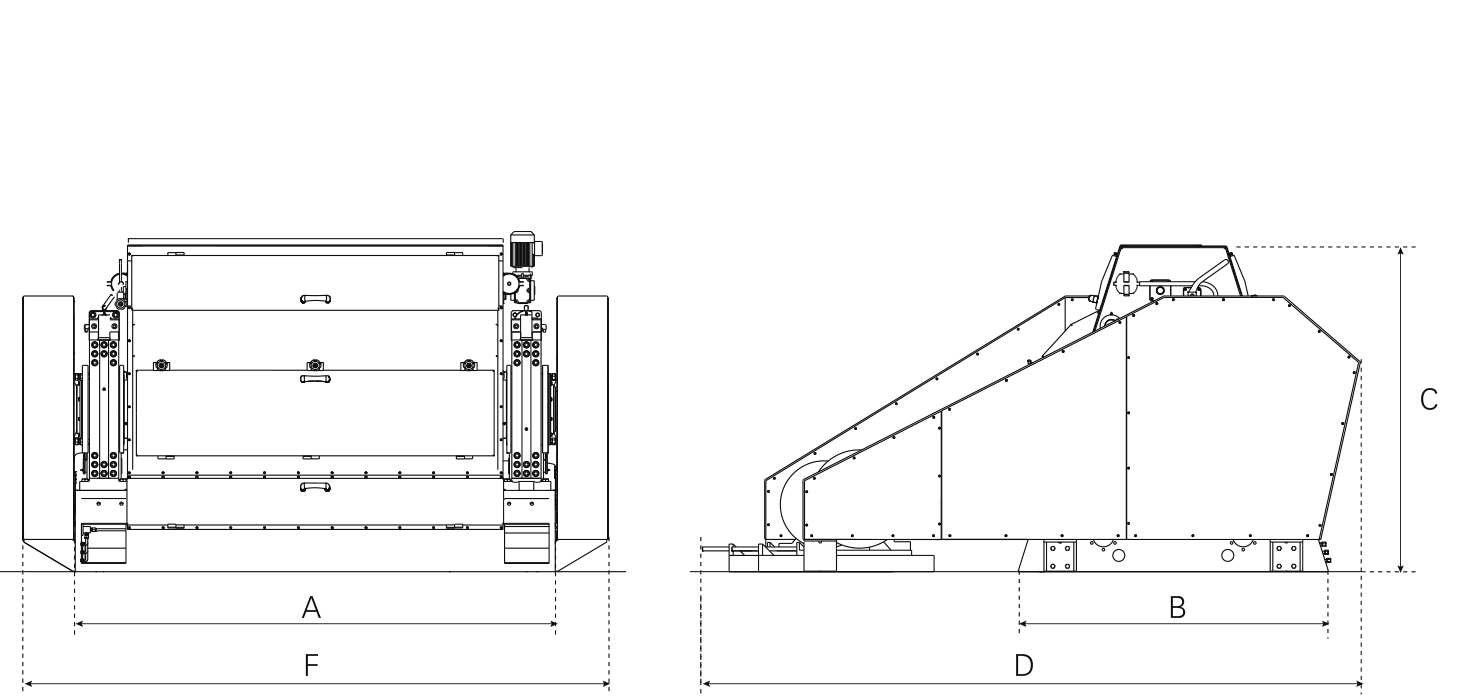

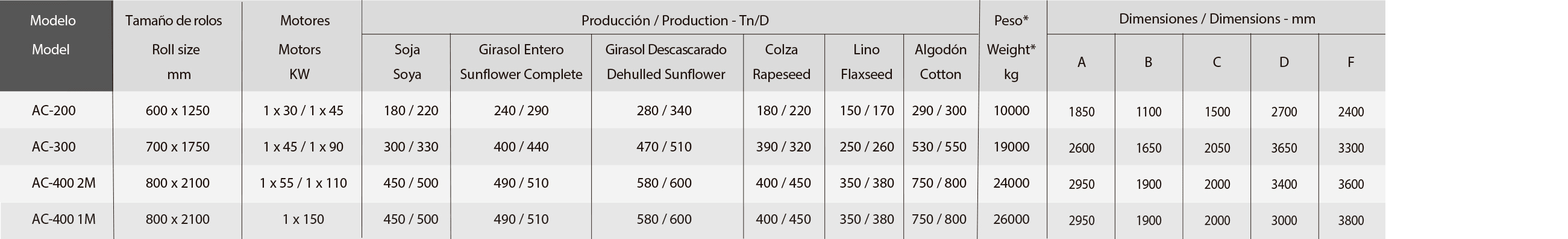

Technical Characteristics and Measures

* Weight with engines